June 19th, 2019

How the Circular Economy Offers Huge Financial and Operational Benefits for OEMs

Sean Sheehan, Wisetek CEO, discusses how the Circular Economy offers huge financial and operational benefits for OEMs.

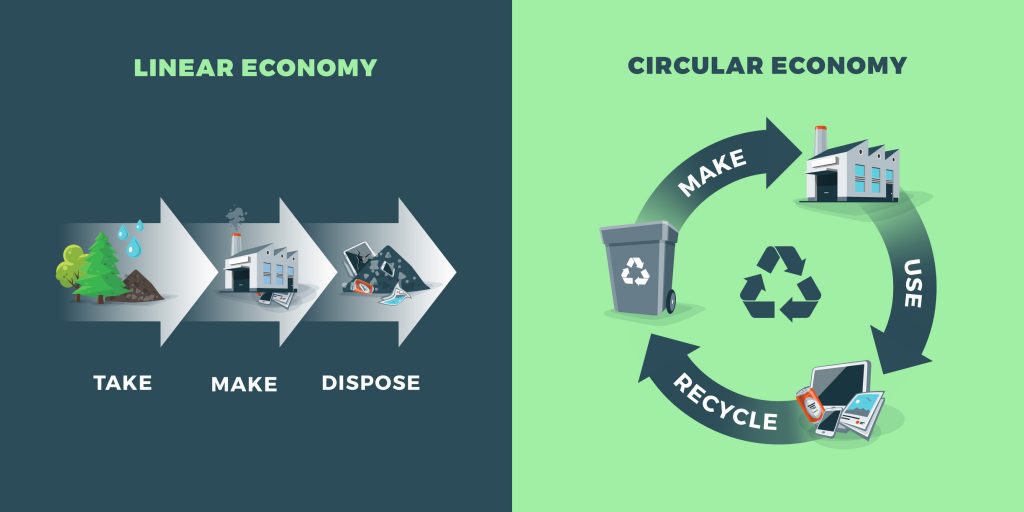

When it comes to the benefits of the Circular Economy, some industries stand to gain more than others. While SMEs – and even individuals – should embrace any form of sustainability, there’s a real economic benefit for Original Equipment Manufacturers (OEMs) to adopt the principles of the Circular Economy. In particular, those OEMs who are involved in the production of IT equipment.